Defence Keeps Going While Other Industries at a Standstill

Construction on Australia's largest defence surface ship project, the Hunter Class Frigate, continues despite COVID-19 pandemic challenges.

Andrew Spence

21 April 2020

Shipbuilding continues despite global pandemic

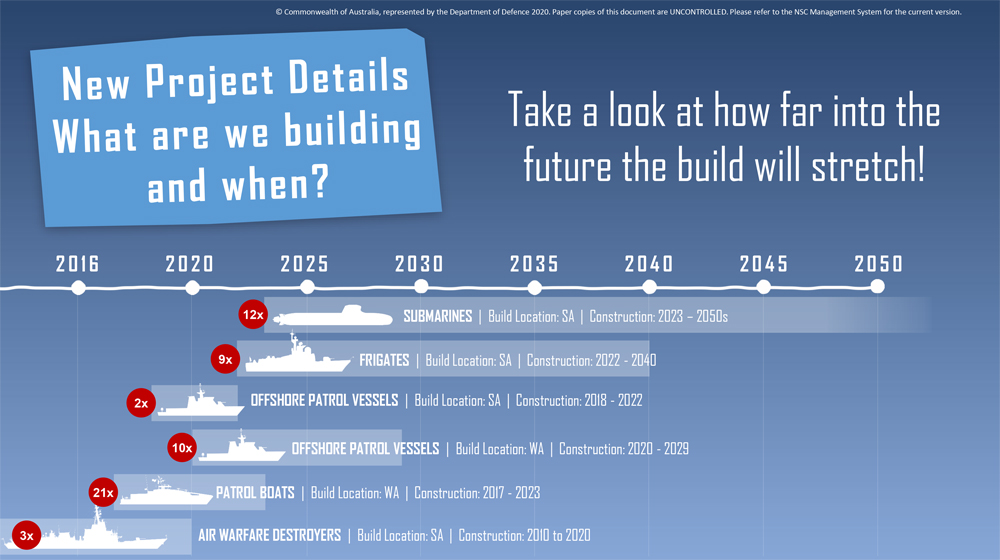

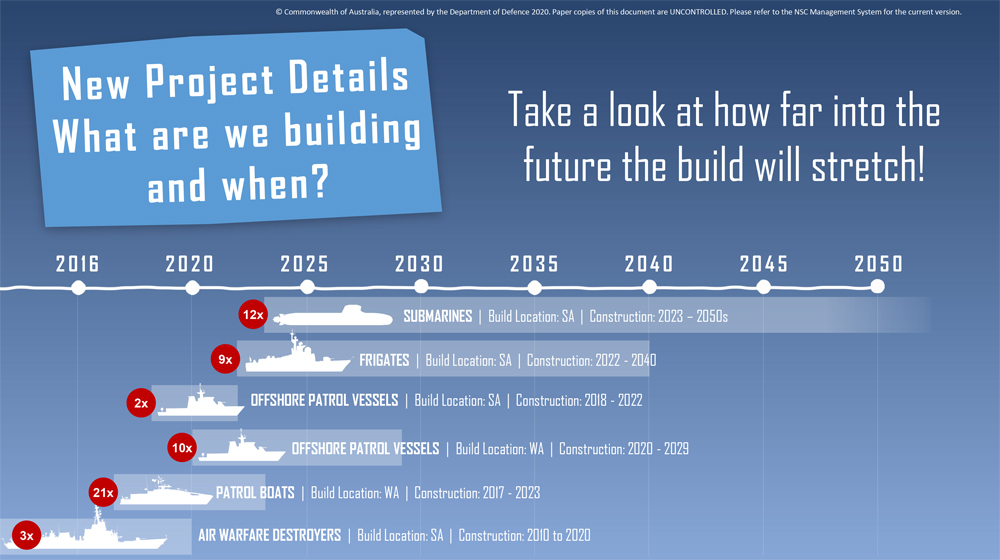

Nine anti-submarine warfare frigates will be built by ASC Shipbuilding at the Osborne Naval Shipyard in Adelaide in what is being described as the largest surface ship project in Australia’s defence history.

The $35 billion Hunter Class Frigate Programme is expected to generate thousands of additional jobs in South Australia and interstate at defence primes and smaller component manufacturers, which are being contracted to supply parts and expertise.

There are approximately 700 people working on the programme. Those numbers are expected to reach 1,000 by the end of the year and 1,500 by mid-2025 before reaching a peak of 2,400 in 2028. The ramping up of shipbuilding programs in Adelaide this year is providing an employment lifeline for South Australia as the state looks for ways to tackle boost jobs growth post coronavirus.

South Australia is pivotal to Australia’s $90 billion National Naval Shipbuilding Enterprise. The last of three Air Warfare Destroyers were handed over to the Commonwealth in a ceremony at Osborne last month where construction of Offshore Patrol Vessels is well underway.

Osborne has been the home of the Air Warfare Destroyer project for more than a decade and was also where six Collins Class submarines were built for the Royal Australian Navy and have undergone ongoing sustainment. It is also expected to be the construction site for12 Attack Class Submarines from 2024.

ASC Shipbuilding is a subsidiary of BAE Systems throughout the Hunter Frigate build process before ownership is returned to the Commonwealth at the completion of the project.

ASC Shipbuilding Managing Director Craig Lockhart said while 70% of Osborne’s staff were working from home and social distancing measures were in place, shipbuilding had been able to continue in Adelaide throughout the COVID-19 pandemic.

“We’re still presenting all the design-based engineering outputs that we need to deliver against the schedule so I think the positive is that defence has kept going when lots of other industries have unfortunately had to stop,” he said. “We’ll be better placed than most sectors to come out of this because it’s largely been progress as normal, we haven’t been that affected by what has been going on."

Lockhard said the Hunter program was well placed to be front and centre in South Australia and lots of other states when Australia emerges from lockdown.

A $535 million upgrade to the Osborne shipyard is almost complete, creating a world-class digital shipyard, which will be key to delivering the frigate program.

ASC Shipbuilding also partnered with BAE Systems and Flinders University to launch Australia’s first digital shipbuilding course, aimed at upskilling the remaining AWD workforce with the latest industry 4.0 technologies and techniques that will benefit the Hunter program and future shipbuilding projects in the state.

The Hunter Class Frigates are based on the Type 26 Global Ship, which BAE Systems is building for the United Kingdom’s Royal Navy in Scotland.

The first of more than 40 ASC shipbuilding staff seconded to BAE’s Scotland shipyards as part of a knowledge transfer are beginning to return to South Australia after up to 18 months in the UK learning how to build the ships.

The two-year building of five test blocks at Osborne will commence in December this year with building of the first frigate expected to commence in 2022.

Lockhart said the digital shipyard and highly skilled workforce at Osborne meant there would likely be future export opportunities beyond the nine Hunter Class frigates.

Lockhart said the digital shipyard and highly skilled workforce at Osborne meant there would likely be future export opportunities beyond the nine Hunter Class frigates.

“Part of why we’re putting so much effort into the knowledge transfer and learning how these ships have been designed and built in the UK and bringing that back to Australia is that we want to be front and centre of the Commonwealth Government’s future shipbuilding plans in both design and manufacture,” he said.

“I want ASC Shipbuilding to build on the success of the Air Warfare Destroyer, to deliver the Hunter Program successfully and to be positioned for the Air Warfare Destroyer replacement and for future export opportunities.

“There’s a whole range of opportunities and it’s really for other governments to decide, but we know there’s a frigate replacement program in Japan, we know the Kiwis will buy ships at some point … so these are all opportunities for us to play some part. I expect ASC to be positioned to harness the world-class facilities we’ll have at Osborne and with that design capability based on Hunter to take a big slice of that action.”

The frigate programme alone is expected to create 1,000 apprentice and graduate jobs throughout the programmes life.

Set up by the Federal Government and headquartered in Adelaide, the Naval Shipbuilding College’s role is to ensure Australia has the right mix of skilled workers to fuel the continuous build. It has so far partnered with 21 education providers to deliver accredited training tailored for the sector.

Naval Shipbuilding College Chief executive Ian Irving said shipbuilding offered well paid, stable employment, which was particularly important in times of economic uncertainty. “If we look at the submarines and the frigates, they are some of the most complex machines [we] will build in the next decade and there’s a great opportunity for male and female students to get the training they need to be job ready and come into this arena.”